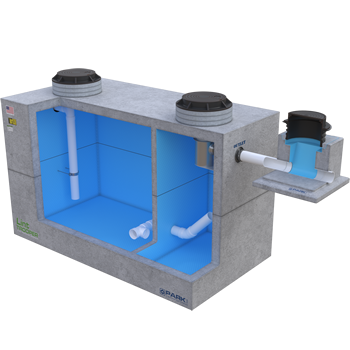

Lint Interceptor

•The ParkUSA® LintTrooper® is used in commercial and institutional laundries to

remove excessive amounts of lint and silt that

may interfere with the proper drainage and

treatment of wastewater. Local plumbing codes

require the installation of a lint interceptor to

pretreat the wastewater.

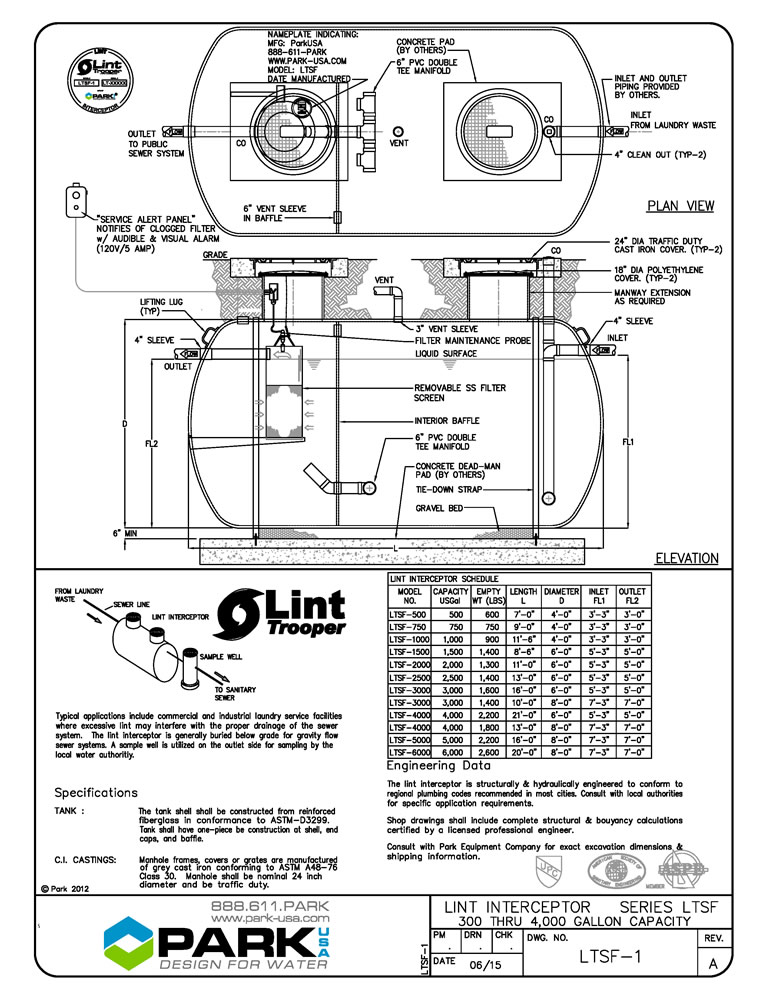

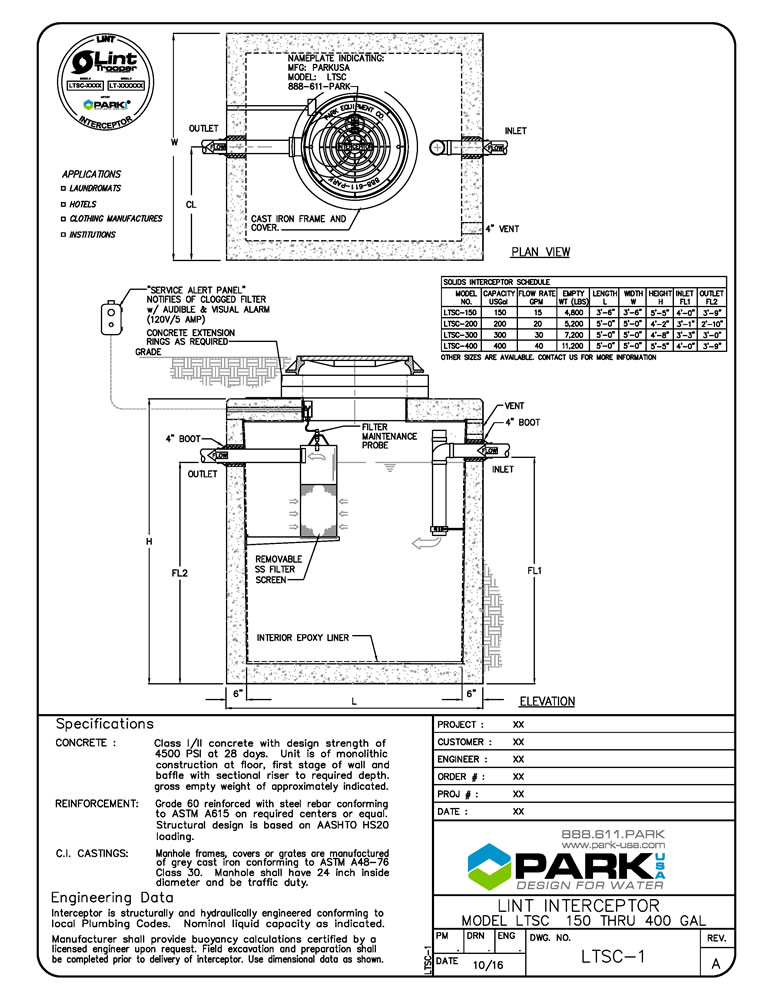

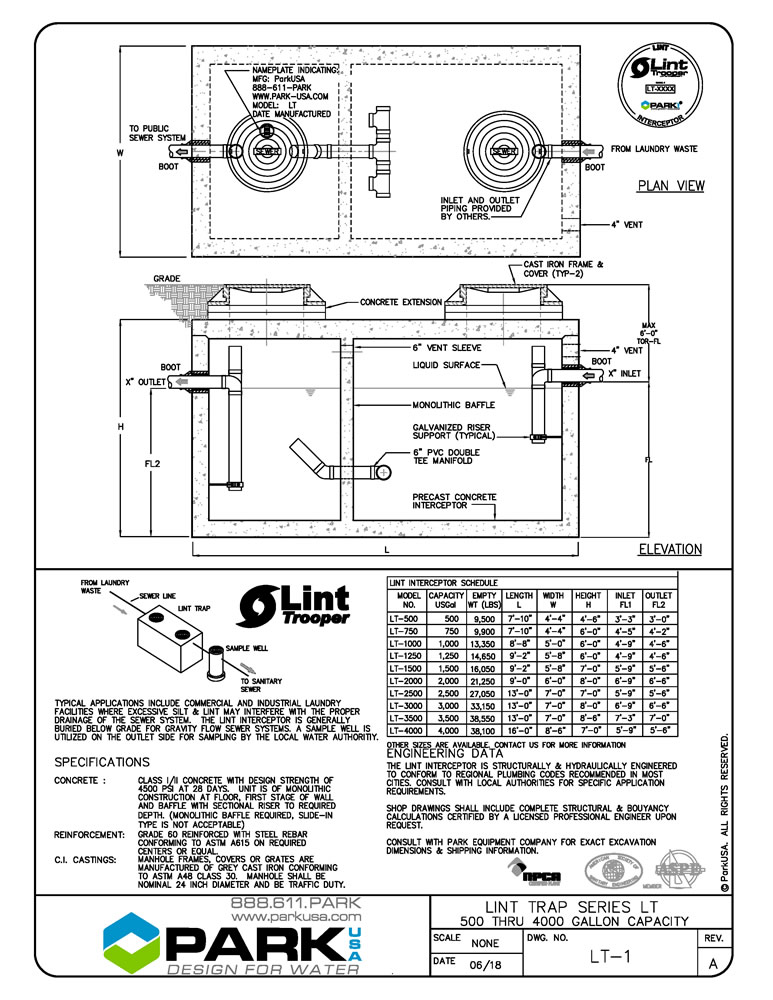

The LintTrooper® is a lint and sediment

interceptor that consists of a

multi-compartment basin and unique

separation technology for lint and sediment

separation. Typical applications include

commercial/institutional laundries,

dry-cleaners, and textile operations. The

waste-water discharge from these facilities

usually contains high quantities of lint, silt,

dissolved and suspended solids, as well as

detergents. The LintTrooper® is compliant

with both UPC and IPC plumbing codes, and

can be equipped with debris screening

technology that prevents string, rags, buttons,

and other materials from entering the public

sanitary sewer system.

Features

Dolor Sit Amet

- Pre-engineered from 500-15,000 gallons

- Precast concrete, polyethylene, fiberglass

or steel

construction - Above or below grade installation

- Custom screen sizes (down to 100

micron)

- Pedestrian or traffic rated

- Remote maintenance alarm

- Interior liners available

- Meets all building codes

The LintTrooper® is typically located outside the building and

buried below grade, where wastewater can exit the laundry via

gravity flow and enter the interceptor. The interceptor contains

multiple compartments where the lint flocculates and floats to

the surface, and heavier solids sink to the bottom. As the

wastewater enters the interceptor’s first compartment, the water

velocity is significantly reduced, allowing for separation and

fall-out of the lint and sediment. Water travels into the second

compartment through the piping manifold, where further

separation occurs. The water exits through an outlet pipe

positioned between the floating and settling layers. Neutral

buoyant particles are further separated by an internal effluent

screen.

The buried interceptor is typically constructed of precast

concrete, providing years of continuous service.

To ensure maximum performance of the interceptor, a sample

well is recommended downstream of the interceptor. As its name

implies, water samples can be drawn and lab-tested to determine

sediment total suspended solids (TSS) content and interceptor

performance.

Additional Resources

File Preview ⬎